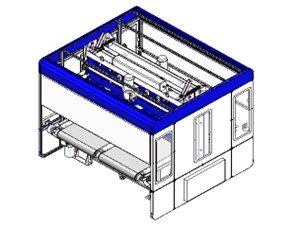

This breaker is designed for rotary or flatbed die cutters.

The machine separates nicks in between die cutted blanks in one direction at a time.The separation is achieved through two clamping pads, one fixed and the other mobile. The upper moving pad pulls the batch away while the lower fixed pad holds down the other side of the stack. The separation points are automatically positioned between two pads and the movement is generated through pneumatic pistons.

The transport of the batches is performed through flat driven belts (or rollers depending on option).

Typical flatbed die cutter application requires double separation, the machine needs to be placed in corner or one after the other, with a turning cross in between.

Plastic bundle conveyor

*Basic parameters:

-Motor power: 1.5KW

-Mesh belt speed: 12-18 m/min (variable frequency speed)

-Load bearing capacity: 500 KG/M ²

-Installation height 750~850mm

-Height adjustable range: ± 50mm

-Mesh belt sprocket: 19 teeth (split type sprocket easy to maintain)

-Mesh belt cushion plate: multi-layer board thickness 20mm

*Main standard components:

-Module mesh belt brand and raw materials: Hairise/HONG’S, pitch 25.4mm, wall

thickness 10-12.5mm, plate material is engineering plastic steel, -40oC~93oC

-Motor brand: Hangzhou Hangjun

-Gear reducer brand: SUPERSTAR

-Diffuse Reflective Optoelectronics Brand: Omron (Japan)

Reviews

There are no reviews yet.